Ford River Rouge Plant Iron Foundry

When completed in 1921, Albert Kahn designed, this steel frame structure, situated about 350 feet east of the Turning Basin Slip, was probably the most impressive single unit of the Rouge. The largest foundry of its kind in the world, it not only poured 2,000 tons of castings each day but housed an impressive machining operation as well. The entire operation was so highly mechanized by a series of conveyors and tracks that little physical labor was necessary. Cupola cars brought huge ladles of molten metal direct from the blast furnaces located on the west side of the foundry where it could immediately be cast into engine blocks. After cooling the castings were routed to the machining department where after 43 different operations they emerged as Model-T engine blocks. By 1922 the foundry was casting 7,700 motor blocks daily for Model T's and Fordson tractors, a figure which increased to 10,055 in 1924.

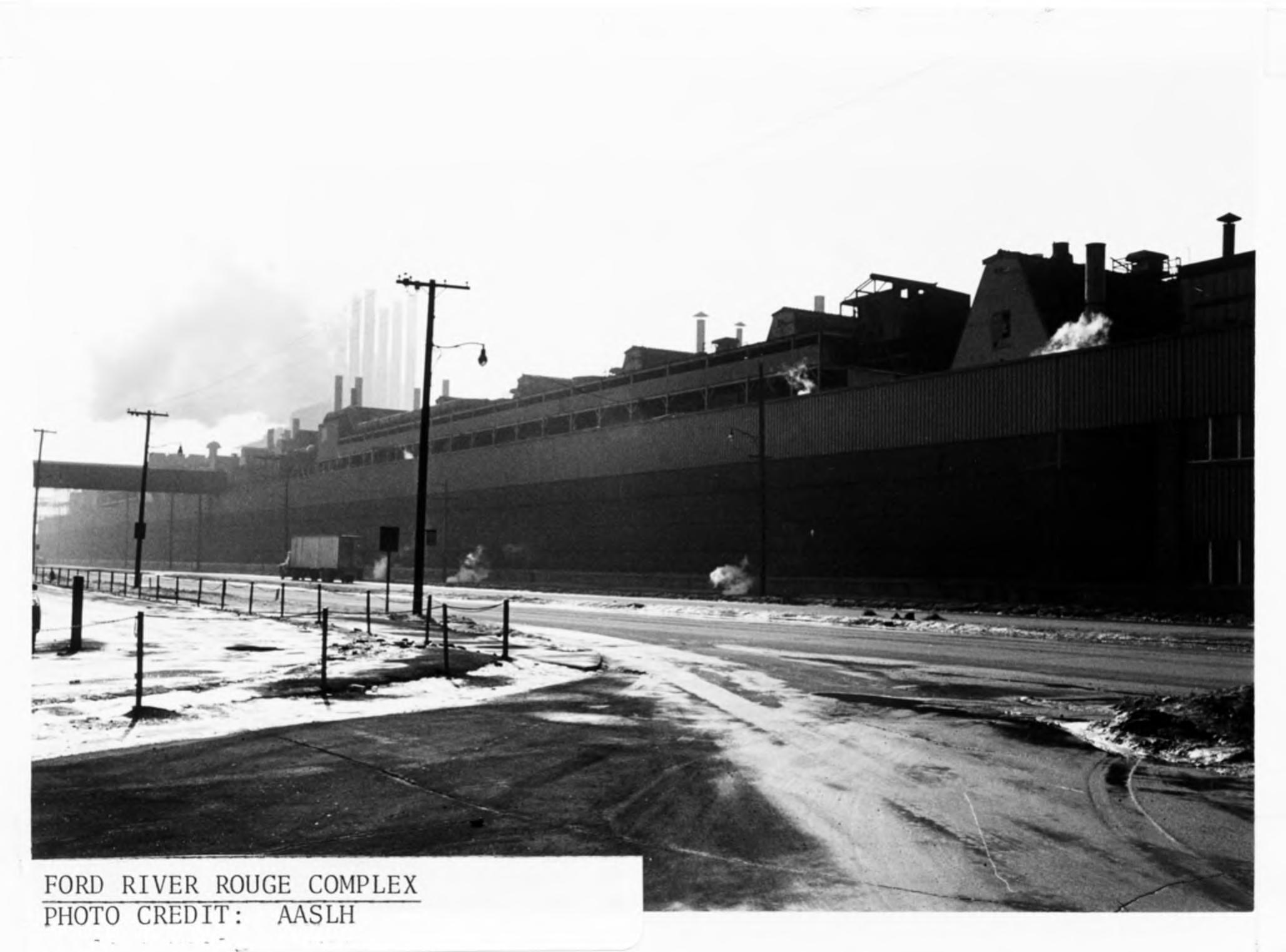

Over the years the foundry has been enlarged somewhat, and now it measures 720 by 1,600 feet. Despite modernization, it retains some original exterior features like its lower walls of brick, its metal-clad upper walls, its gigantic steel sash windows, and its clerestory monitored roof which provides much lighting for the interior. Still serving its original purpose, the Dearborn Iron Foundry remains one of the largest production foundries in the United States.

View from east, showing east facade of Dearborn Iron Foundry