Ford Long Beach Assembly Plant Shed A

The 1927 "Plot Plan" designed by Albert Kahn, Inc. does not illustrate Shed A. Furthermore, the building permits do not indicate a construction date for the structure. The first illustration of this structure, labeled as Shed A, is on a 1947 map of the Long Beach Assembly Building (Plot Plan 74, 1947, LBP). The structure was situated east of the Pressed Steel Building , north of Cerritos Channel and south of Sheds B, C and D. A 1948 drawing of the Bulkhead for the Ford Motor Company-Plot Plan (Davies, Plot Plan 1949, LBP) has a label "Carpenter Shop" within the outlines of this L-shaped building. "Carpenter Shop" was the label used for this building on a map that the Ford Motor Company had prepared as part of a "Specifications" for sale of the property in 1959 (Long Beach Assembly Plant, Specifications in offer to sell, 1959, LBP). A 1982 map of the former Ford property prepared by International Rectifier, Corp., Rachelle Laboratories, Inc. (1982, LBP) illustrates this building as."Warehouse No. 5." Hence, the structure was used as a Carpenter Shop during the operations by the Ford Motor Company. The building apparently functioned as a storage building during the successive occupations at the plant.

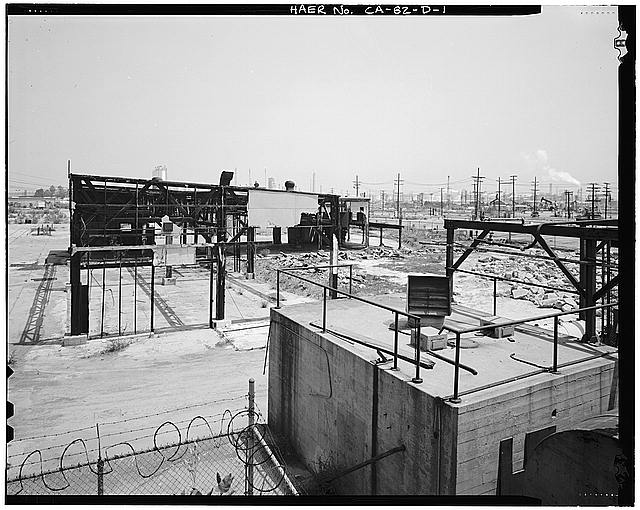

Shed A was an L-shaped structure located ca. 40 feet east of the Pressed Steel building. Dimensions for the structure were ca. 190 feet by 65 feet along the east/west axis, by 130 feet by 65 feet along the north/south axis. The floor space was 7,900 square feet (Long Beach Assembly Plant, Specifications in Offer to Sell, 1959, LBP).

This structure was built upon a poured concrete pad. This pad was probably supported by pilings in the same fashion as described for the Assembly Building. Poured concrete piers rested on the concrete pad. These piers supported vertical, laminated beams or posts that formed the superstructure of the building. The posts were fabricated from three to five 2 inch by 12 inch milled planks, that were fastened with carriage bolts. The posts were horizontally spaced at 30 feet center intervals. The posts were connected by a series of horizontal trusses that rested on wooden cleats, ca. 3 feet below the tops of the posts. These trusses were located along the west, north, and east exterior walls, as well as the two interior partitions. In effect the post and truss construction resembles "balloon framing," a popular building technique in the mid-19th through early-20th centuries. The south wall of the building was balloon framed with milled 2 inch by 4 inch milled lumber. Horizontal braces and "A"-shaped braces provided additional support between the upright posts on the exterior and interior of the structure.

Wall construction was facilitated with stick framing that ran from the bottom of the trusses down to the concrete pad where they were anchored. Drywall was applied to the exterior and interior of the buildings frame. The exterior walls were finished in stucco and painted a tan color. The drywall on the interior walls was plastered and painted.

The roof was a "shed-type" with a 1 percent slope west to east tending slope. The roof was constructed by laying 2 inch by 8 Inch planks or rafters across the top and perpendicular to the trusses that spanned the posts. Purlins measuring 2 inch by 4 inch ran atop the rafters. Wooden sheathing was affixed to the top of the purlins, and supported the asphalt roofing material,

A wooden paneled door mounted on a sliding rail or track, located on the interior of the building's north side, was the only entrance noted in this ruined structure. Albeit other entrances were probably present in other walls of the original structure. Fenestration was absent due to the fire damage.

Mechanical systems were Intact in the northern portion of the building. Water and air pipelines, as well as vestiges of the electrical system are present. Remnants of the overhead fire sprinkler system was in-situ. Light fixtures were affixed to the undersides of the rafters. Several pipes and vents protruded through the roof from the interior of the structure. It should be stressed that the ventilation and associated mechanical systems were the only physical traces of the machinery that was formerly used in this Carpenters Shop.

This shed embodies the same characteristics represented in the main assembly building. The building was constructed with a massive frame that permitted the optimal use of floor space, yet allowed ample natural light and access into the buildings.

SHED A RUINS FROM ATOP CORNER OF DIKE, LOOKING NORTH-NORTHEAST.

SHED A, INTERIOR, TO NORTHEAST CORNER OF MAIN PLANT. VIEW TO NORTHWEST.